Lean Construction

If you walk onto the floor of almost any factory, you’re likely to see lean practices in place that improve efficiency and productivity. These practices have spread to many other industries beyond just manufacturing, and they’ve had a significantly positive effect on many organizations. Unfortunately, the construction industry had been mostly untouched by these practices and has even become less productive than it was 20 to 30 years ago. More complicated building systems and a workforce that was losing more experienced professionals each year to retirement exacerbated the issue, combined with several other factors. The industry needs systems to encourage face-to-face collaboration and knowledge-sharing. As we at Story Construction like to sum it up, it’s time to bring joy back to our job sites.

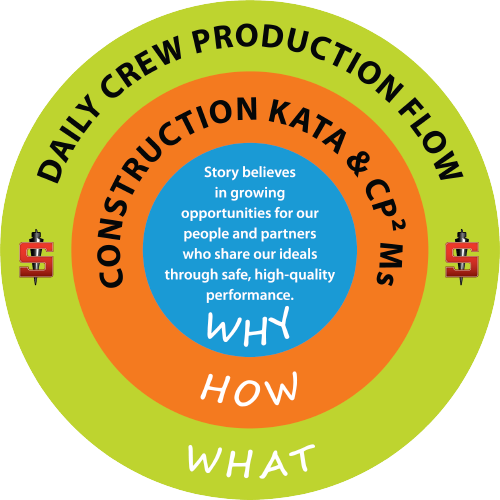

Story believes in growing opportunities for our people and partners who share our ideals through safe, high-quality performance.

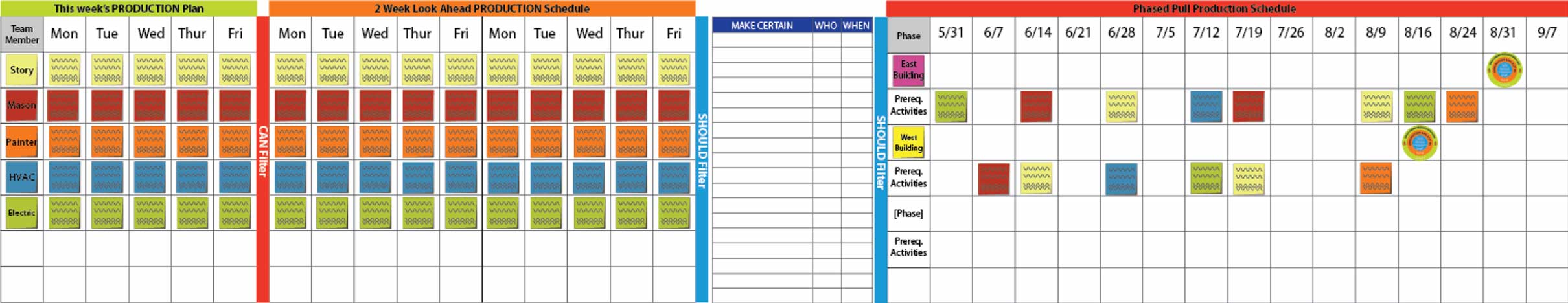

Construction Production 2.0

Our approach to lean construction is called Construction Production 2.0. CP 2.0 is a low-tech, highly visual system that utilizes a large gridded planning board and Post-It® notes in conjunction with purposeful meetings and culture-building tools. This system has been used on every Story Construction project since 2013, and is used in some form throughout the company, from design and preconstruction to marketing and accounting. Each Story job site has a trailer used specifically for this system.

For Owners

From pre-construction through punchlist, this system provides transparency for owners to truly see the work happening on site and meet their commitments.

Ultimately this system impacts an owner’s bottom line by providing a predictable and reliable environment for subcontractors and suppliers, positively impacting the planning and performance of the work being done.

For Employees

Elements of Construction Production 2.0 include important pieces of professional development for Story employees.

We utilize Construction Kata and continuous improvement methods to maximize learning opportunities for employees at all levels of the company.

For Partners

Joyful job sites mean project partners can do their work without sifting through bad or missing information.

Construction Production 2.0’s rhythm of team meetings, information status sessions and MakeCertain! tasks make this a reality on Story’s projects.